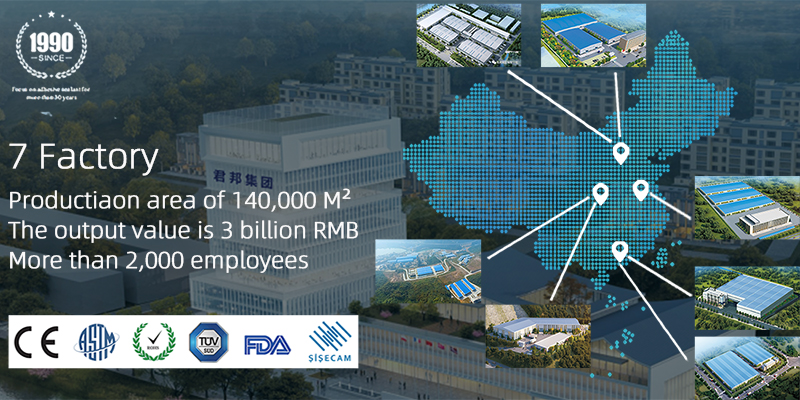

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Online Exporter Manufacturer Adhesive Two Component Silicone Insulating Glass Secondary Sealant Hot for Selling, We play a leading role in giving buyers with high-quality goods fantastic provider and competitive selling prices.

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for China Silicone Sealant and Sealant, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to “create first-class products” as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Product Description

JB9980 Silicone insulating glass sealant is a two component, neutral curing silicone sealant specifically developed for the manufacturer of high performance insulated glass.

Feature

● Insulating glass manufactured by JB9980 conforms to I SR-20HM-JC/T 486-2001.

● Neutral cured, no corrosion, nonpoisonous.

● Excellent stability in a wide range temperature at -50℃~+150℃.

● Excellent weatherproof feature and a high resistance to UV radiation, high temperature and humidity.

● JB9980 sealant has excellent unprimed adhesion to most coated or not coated glass. It is compatible to neutral series

Use Limitations

JB9980 silicone sealant should not be applied in the following conditions:

It could not be used for structural curtain wall glazing.

It should not contact with any acetic sealant.

Please read company’s technical files before application. Compatibleness test and bonding test must be done for construction materials before application.

Processing

Please make sure A and B well-mixed before tooling. Use could also change the proportion of mixture to adjust curing speed according to physical demand (Volume

ratio 8:1 ~ 12:1).

The substrate to be in contact with the sealant must be clean, dry and free of all loose materials, dust, dirt, rust, oil, and other contaminants.

JB 9980 could be used on automatic line production and manual line production of insulating glass. Also could match with hot melt butyl rubber.

Storage

Storage period is 12 month from the date of manufacture when stored at dry and airy, below 30℃ conditions.

Safety notes

During curing VOC is released. These vapors should not be inhaled for long periods or in high concentration. Hence, good ventilation of the work place is necessary.

Should uncured silicone rubber come into contact with eyes or mucous membranes, the affected area must be rinsed thoroughly with water as irritation will

otherwise be caused.

Please do compatibility testing before construction.

Keep out of reach of children.

Mixture Ratio

Part A is white color, Part B is black color.

A/B – Volume ratio 10:1 (Weight ratio: 12:1)

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Online Exporter Manufacturer Adhesive Two Component Silicone Insulating Glass Secondary Sealant Hot for Selling, We play a leading role in giving buyers with high-quality goods fantastic provider and competitive selling prices.

Online Exporter China Silicone Sealant and Sealant, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to “create first-class products” as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

1, glass, stone, aluminium curtain wall structural bonding and sealing

2, glass lighting, metal structure engineering bonding and sealing

3, hollow glass two bonding and sealing

4, plastic steel doors and windows bonding and sealing

5, a variety of other industrial use.