The quality and price of door and window silicone sealant on the market are uneven, and some are very cheap, and the price is only half or even lower than that of similar well-known products. The physical properties and aging resistance of these low-priced and inferior door and window silicone sealant cannot meet the long-term service life of doors and windows. At the same time, quality accidents caused by low-priced and low-quality door and window glue may cause customers to pay several times or even dozens of times the cost of purchasing glue, and even cause serious social impacts and damage corporate reputation. Here, we suggest that users must choose door and window silicone sealant with guaranteed quality.

oil-filled weathering sealant cracking hardening

Oil-filled weather-resistant sealant causes pollution of aluminum panel curtain wall

The quality of door and window silicone sealant is related to the quality of raw materials, formula composition, production process, quality control system and other factors. Here, users are advised to understand the R&D capability, testing level, production process, production equipment and quality control system of the concerned brand manufacturers. Junbond factory welcome all customers visit our factory, if you can’t come to China, we supply online video chat to introduce our factory.

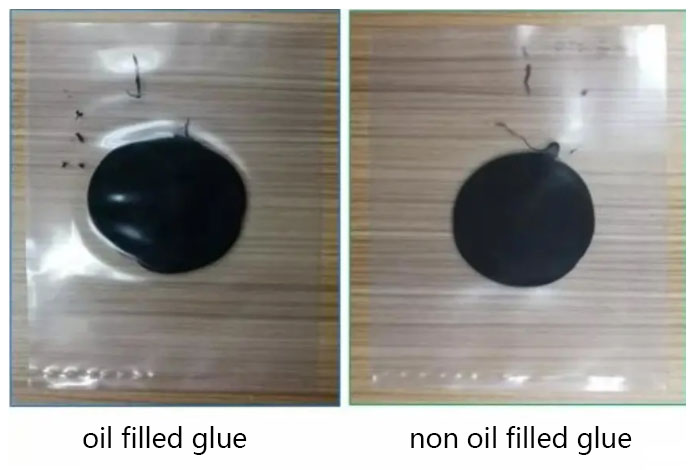

A large part of the low-priced and inferior silicone sealants on the market are cost-reduced by replacing the expensive silicone base polymers with a large number of various alkane plasticizers (white oil, liquid paraffin, collectively referred to as mineral oil).The identification method is very simple, only a flat soft plastic film (such as agricultural plastic film, PE film) is required

The method utilizes the principle that the mineral oil has poor compatibility with the silicone sealant system and is easy to migrate and penetrate from the silicone sealant system. When the oil-filled silicone sealant is in full contact with the plastic film, the mineral oil will penetrate into the plastic film, causing the plastic film to become uneven. This method is applicable to both one-component and two-component silicone sealant . The experimental process also found that: the larger the amount of filled mineral oil, the shorter the shrinkage time of the plastic film and the more obvious the shrinkage phenomenon.

During the test, the sealant sample was smeared on the plastic film and scraped to make it have a larger contact area with the plastic film, as shown in the figure. After a few hours, usually within 24 hours, the sealant can be identified whether it is oil-filled or not. If the sealant is oil-filled, the plastic film in contact with it will shrink and wrinkle, while the non-oil-filled sealant will not shrink and wrinkle in contact with the plastic film even if it is placed for a longer time.

JUNBOND series of products:

- 1.Acetoxy silicone sealant

- 2.Neutral silicone sealant

- 3.Anti-fungus silicone sealant

- 4.Fire stop sealant

- 5.Nail free sealant

- 6.PU foam

- 7.MS sealant

- 8.Acrylic sealant

- 9.PU sealant

Post time: Jan-14-2022